AIR TIGHTNESS

for warmer homes & saving money

It´s a common misbelief that air tightness is "a complete new thing", which has been developed within the last few years and just for the sake of making construction more complicated and expensive.

In reality, this strategy is almost as old as the mankind, settled in accommodations. Vikings used moss and grass for closing gaps at their log homes for better protection against arctic breeze. Buildings in many African and Asian regions have been covered with clay to be protected against (sand) storms. Igloos were always covered with an additional layer of snow, to have the inside secured against wind and cold.

Fortunately we´re not affected by such extremes here in Ireland, but we still have to take attention to air tightness for our buildings.

What effect does inappropriate air tightness create in your home?

First and foremost you´ll notice it every winter by having losses of living comfort,

caused by draughts and heat loss.

Also, the unwanted loss of heating energy will lead to higher efforts for keeping the house warm.

A totally underestimated aspect is the potential risk of damages to the building structure due to lack of air tightness, mostly caused to timber structures like roofs or stud walls.

And a health risk can be created by Radon, accessing the building through gaps and cracks in the building envelope.

Loss of comfort

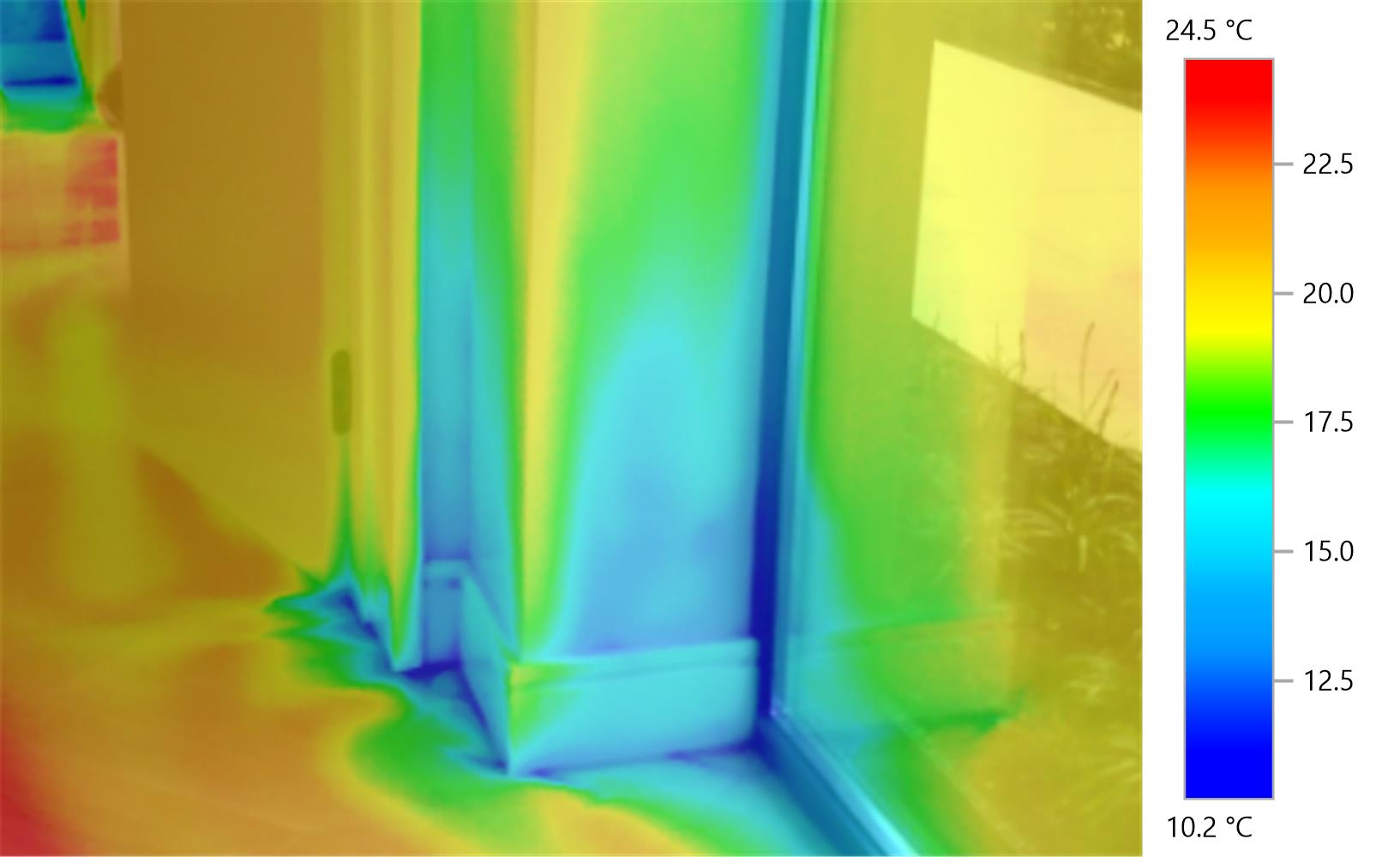

Draughts, caused by by a leakages in your building envelope, will create discomfort and lower the room temperature in your home.

Waste of energy

Uncontrolled heat loss, caused by poor air tightness performance, will lead to a higher heat demand, to keep the house warm in the cold season.

Structural damages

Lack of air tightness can create structural damages in the cold season. Warm air is escaping through the building envelope and could lead to condensation.

What you should know about air tightness

- What is an air tightness layer?

- Where to place the air tightness layer?

- Do I need air tightness at all?

- Can I make my building too air tight?

- What is currently required by Irish regulations?

- Can I measure the air tightness grade of a building?

- What means air permeability?

- What means air change rate?

- 50Pa differential pressure is equivalent to... ?

- Can I save money by having an air tight home?

- What would it cost, to make my home air tight?

A message to private clients:

Due to limited capacity, we are no longer in the position to provide quotations for airtightness materials.

All products are still available in our online store, but you must be clear about what you need and in what quantity.

Any email enquiries will not be processed.

How to achieve good air tightness ?

What details need to be considered

Standard Air Tightness

A standard air tightness performance to comply with most building regulations can be achieved by taping all doors and windows internally and installing air tightness membranes. Please note that Irish standards for air tightness are lower in comparison to other European countries.

Air Tightness above Average

For an air tightness result above the average, you´ll need to take additional attention to details like floor-to-all junctions, chases for conduits on cavity walls and services through

the air tightness layer. Better attention to details will lead to better air tightness results.

Air Tightness for Passive House

To achieve Passive House standard (0.6 ACH) for air tightness, you should take an adequate planning, installation and monitoring into consideration. Also, it´s essential to have other trades like electricians or plumbers on board, to ensure that your effort for perfect air tightness is not counteracted by others.

prodomo Ireland is there to help you on your way to an successful air tightness performance for your project, no matter what kind of building you have

and what type of client you are.

Air Tightness for new build

Air Tightness for nZEB

Air Tightness for Passive House

Air Tightness for Architects/ Engineers/ Contractors/ Developers/ Self-Builders

Air Tight Window Taping

Select the right strategy for your windows & doors

The best window is worthless without having the surrounding joints completely insulated & sealed. The sealing works as an air tightness and vapour control layer. Expanding foam is good for insulation purposes but doesn´t create a permanent air tight & vapour check barrier. That´s why a comprehensive window sealing is so important. An appropriate sealed window eliminates the risk of draughts, heat loss and condensation/ mould.

-

Standard window tape

-

Self-adhesive window tape

-

External sealing of windows and doors

-

Window sealing with air tight paint

-

Window sealing with approved sealant

-

Taping of roof windows

Air Tight Membranes

To protect your building structure

Air Tightness Membranes prevent unwanted air infiltration (draughts) and heat loss. But their main task is, to protect the timber structure of your building (e.g. roof structure) against condensation, mainly caused by warm & humid room air in the winter. That´s why the most building professionals call and specify air tightness membranes as vapour control layers.

Air tightness & vapour control layers have to be installed always at the warm side of the building shell.

-

Highest Ceiling

-

Pitched Roof

-

Vaulted Ceiling

-

Timber Frame

-

Flat Roof

-

Through floor joists

What else needs to be considered for a complete airtightness strategy ?

Keep the overall picture in mind

In recent years we all noticed how important it is, to create a full air tightness strategy, which includes every part of the building.

The more air tight we want to have our building, the more attention we need to put into small details, to prevent the enhanced risk of uncontrolled air infiltration through these areas.

Spots like chasings for conduits on perimeter walls or junctions between floor and walls are becoming more important when it comes to a functional air tightness with values of 1.5 ACH (air changes per hour @ 50Pa differential pressure) or less.

But how can you make your complete house steadily air tight?

By just using air tight membranes, tapes and plaster coating for certain building areas only?

All three solutions above do create an air tight layer, but you need to pay a particular attention to have a complete airtightness strategy for the whole building envelope in place.

Air Tightness Testing & Training

to improve and verify the performance of your home

As per 01.10.2024 - this service is not longer available

Survey and consultation for (existing) homes

As per 01.01.2024 - this service is not longer available

Training Courses (for air tightness)

As per 01.09.2023 - airtightness training courses for the public have been discontinued.

Is there a difference in air tightness products

The more expensive, the better ???

You´ll always find self-proclaimed experts, advising that good air tightness performance is depending to a certain brand or product. Also, you can find plenty of marketing promises about the grandiosity of certain products.

But is there a such noticeable difference in air tightness products in reality, which would justify the enormous price differences?

Well, it´s like almost everything in life - when you ask two people about, you´d probably receive 3 opinions. But in the most cases the personal preferences stand over reliable facts from science and reality in construction business.

An interesting fact about air tightness products can be found in one of the Passive House Institute publications, where their first Passive House development in Darmstadt, Germany has been surveyed and re-tested 25 years after the houses have been built. No noticeable deterioration in air tightness performance was observed, even though at the time the houses were built there were no special products for air tightness available and therefore existing products such as builders film and acrylic sealants had to be used instead of the "superior materials" available today, which are ultimately only made of relatively simple hydrocarbon compounds (plastic) and were actually originally manufactured for other purposes.

prodomo Ireland

Your specialist for air tightness, thermal brackets & energy saving.

We deliver products and solutions to Irish clients for more than seven years when it comes to air tightness and thermal brackets for doors & windows. To allow clients all over Ireland to benefit of our knowledge, experience and "Teutonic thoroughness", we´re focused on consultation & supply . If you´re looking for installation as well, we might can recommend a qualified tradesman.

Shop ONLINE