Triotherm thermal structural supports for windows & doors !

Say Goodbye to inadequate support strategies

We´ve all seen that certain type of creativity when it comes to potential solutions for structural door & window support, mainly created with plenty of effort but still poor.

Installing windows and doors has to become more challenging over the last decade due to permanently increasing insulation requirements and heavier windows and doors, mainly caused by triple glazing.

The growing demand for large-sized sliding doors and floor-to-ceiling windows in new builds, as well as new insulation methods like external wall insulation, is putting pressure to architects, builders and window suppliers regarding practical solutions for supporting windows and doors.

The most previous attempts for supporting windows and doors were not practical for the following reasons:

- Wrong material (e.g. timber with a high risk of rot)

- Risk of heat loss (e.g. supports made of concrete or steel)

- Complicated installation (e.g. bespoke brackets and fixings)

Why should you opt for Triotherm thermal structural supports ?

Learn more about the benefits of thermal breaks for around doors & windows

Triotherm for door thresholds

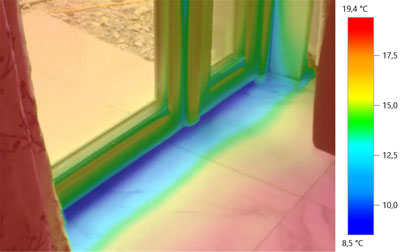

The thermal image overlay was taken in March 2022 at the bottom of a french door in an existing building, which got recently a deep home energy upgrade through a leading One-Stop-Shop for nZEB retrofit.

Unfortunately no further attention has been taken to reduce the thermal bridging at the door threshold level during the retrofit process.

As a result you can clearly see the significant heat loss through the floor area, with temperatures at the door threshold, equivalent to ambient temperature. The floor area further inside of the room is significantly warmer, thanks to the new installed underfloor heating.

Triotherm for windows in the insulation layer

The window installation in the insulation level (EWI) for a new build was realised at the beginning of 2022 by using steel brackets. This results in an increased installation effort as well as a potential deterioration of the overall thermal insulation value of the window (as you can see in the Passive House Institute study further down below).

Since the load is only transferred at certain points, the correct dimensioning of the fasteners is also extremely important and potentially challenging.

The outer sealing level, to prevent water ingress, is very difficult to create, because the steel brackets hinder a clean and continuous seal. Likewise, the insulation material must be recessed around the brackets, which can easily lead to thermal bridging.

Load Transfer

The weight of the door or window must be transferred into the building structure securely , to ensure the functional performances like daily use, rain shelter and wind protection.

Insulation Performance

Low u-values of doors & windows will be degraded by thermal bridging, caused by the use of highly heat-conductive materials (e.g. steel & concrete) or wrong location .

Secure Installation

The best theoretical installation detail is useless when it can´t brought forward into reality. Efficiency and simplicity are the main challenges for a successful installation on site.

How to achieve the secure support of your windows and doors without thermal breaks ?

By using the TRIOTHERM System - the most advanced thermal structural support system for doors & windows

Which key details make the Triotherm thermal structural supports so unique ?

Load Transfer

Triotherm guarantees a load transfer of at least 200kg per 10cm, even in the pre-wall installation version. The secure fastening is part of the Triotherm System and thus simplifies construction processes.

Insulation Performance

The thermal conductivity for the Triotherm+ profile is less than 0.040W/m²K (only), which means that the thermal insulation properties of the selected windows and doors are hardly deteriorated.

Simple Installation

Triotherm+ thermal supports come in lengths of 1,175mm with maximum weight of 4kg per length. This ensures an easy transport and handling as well, thanks to the integrated dovetail joints.

Using the Triotherm thermal structural support system for doors and windows is creating noticeable relief for architects, builders and window suppliers. However, the homeowner benefits most from the advantages of Triotherm thermal brackets because she can enjoy her windows and doors without any restrictions in terms of use and comfort.

All Triotherm components have been extensively tested for various parameters, to ensure that they´ll meet and exceed all required specifications and building standards.

The above logos demonstrate the most important certifications for Triotherm. By clicking the selected logo, you can access detailed information. Please do not hesitate to get in contact for any further certifications like EPD, Evidence of Performance by ift Rosenheim, EMI Code or whatever else you´d need.

Triotherm benefits & full specs

- + highly load bearing

- + less thermal bridging

- + infinitely extendable

- + easy to handle & cut

- + resistant to ageing

- + simplified building detail

- + CE certified

- + Passive House certified

- + 100% recyclable

Examples of application for Triotherm+ thermal structural supports

Due to its excellent properties in terms of load transfer and insulation performance, the use of Triotherm thermal brackets is very versatile.

In general, Triotherm thermal brackets can be used in all common building structures, such as cavity wall, block-on-flat, timber frame, ICF (insulation concrete formwork) or SFS (steel frame systems).

We at prodomo Ireland would like to guide you about the different installation details for Triotherm thermal brackets.

Are you in need of more installation details for Triotherm structural supports?

Just click on the images down below, to avail of further information for your Triotherm installation detail.

Case studies for Triotherm thermal structural supports

Learn more how Triotherm simplifies building details in reality.

Please have a look at the following case studies, where Triotherm+ thermal brackets have been used to secure the required load transfer for windows & doors without thermal bridging on various locations here in Ireland..

Case Study No. 1

Triotherm+ thermal supports guarantee the ideal installation of doors and windows in the external wall insulation layer for a new build.

Case Study No. 2

Triotherm+ thermal supports were used in a nZEB reftrofit, with 200mm EWI and windows shifted beyond blockwork.

Case Study No. 3

Triotherm+ thermal supports have been used as structural support for doors and windows on various building projects.

prodomo Ireland

Your specialist for air tightness, thermal brackets & energy saving.

We deliver products and solutions to Irish clients for more than seven years when it comes to air tightness and thermal brackets for doors & windows. To allow clients all over Ireland to benefit of our knowledge, experience and "Teutonic thoroughness", we´re focused on consultation & supply . If you´re looking for installation as well, we might can recommend a qualified tradesman.

Shop ONLINE